In biopharmaceutical production under GMP conditions, cleaning and sterilizing process equipment is essential to guarantee final product quality. CIP and SIP systems are standardized solutions that ensure tanks, piping, heat exchangers, sensors, and contact elements remain contamination-free between batches. Their use is critical in environments where reproducibility, traceability, and regulatory compliance are priorities, especially in facilities handling sterile, sensitive, or high-value products.

CIP system (Cleaning In Place)

A CIP system enables automated cleaning of the interior of process equipment without disassembly, significantly reducing downtime and the risk of cross-contamination. A typical sequence includes pre-rinsing with water, application of detergent solutions (usually alkaline or acidic) at controlled temperatures, intermediate rinses, and a final rinse with purified water or WFI (Water for Injection), depending on the required cleaning level.

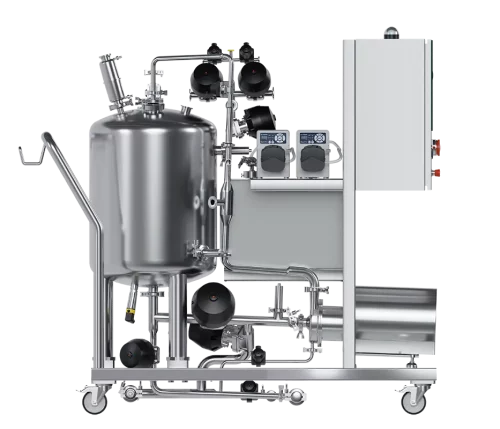

Key components of a CIP system include:

- Tanks for preparation and storage of cleaning solutions, with agitation and thermal control

- Distribution circuits with dosing pumps, control valves, sanitary manifolds, and a design that avoids dead legs

- Sensors for continuous monitoring of temperature, pressure, flow rate, conductivity, pH, and contact time

- Control software with predefined recipes and electronic validation

The equipment design is crucial. It must ensure complete drainage, smooth surfaces, and sanitary connections. Additionally, the CIP cycle must be validated under “worst-case” conditions to ensure its effectiveness in extreme scenarios.

SIP system (Sterilization In Place)

The SIP system sterilizes process equipment by injecting clean steam, typically at temperatures of 121°C or higher for a defined period. This process eliminates all viable microbial life, including resistant spores, ensuring asepsis before the next production cycle.

Critical parameters of an SIP cycle include:

- Controlled temperature and pressure, with precise recording of each phase (preheating, sterilization, cooling)

- Validation of uniform steam distribution throughout the system using temperature probes and steam penetration tests

- Traceable cycle documentation with electronic signatures

- Integration with SCADA or MES systems for centralized monitoring, alarms, trends, and automatic reporting

SIP system design must consider steam-compatible materials, proper thermal insulation, condensate control, and continuous drainage during the sterilization phase.

CIP and SIP integration in GMP environments

Combining CIP and SIP systems in an automated workflow offers clear advantages in efficiency, reproducibility, and regulatory compliance. These systems can operate sequentially or in parallel, depending on plant configuration, minimizing changeover times and ensuring rapid equipment availability. In multiproduct processes, proper CIP and SIP integration is critical to avoid cross-contamination and ensure inter-batch validation.

An effective integration should include:

- Full cycle validation with DQ/IQ/OQ/PQ protocols

- Execution traceability through electronic records, audit trails, and electronic signature systems

- Alarms and interlocks for critical deviations such as pressure drops or out-of-spec temperatures

- Connectivity with other plant systems (ERM, Historian, BMS), enabling integrated management of quality, maintenance, and production

- Cycle efficiency evaluation through OEE and performance parameters

Technical and regulatory advantages

- Compliance with international regulations (FDA, EMA, PIC/S, WHO).

- Significant reduction in human error thanks to full automation.

- Standardization of cleaning and sterilization processes across production units.

- Improved operational efficiency by reducing downtime between batches.

- Better resource management (water, heat, energy) through optimized cycles.

- Easier preparation for regulatory audits and generation of compliance reports.

Conclusion

The implementation of CIP and SIP systems is a fundamental pillar of quality assurance in biopharmaceutical environments. These systems not only ensure safe cleaning and sterilization of equipment but also optimize operation time, improve process consistency, and strengthen regulatory compliance. TECNIC contributes to this mission with tailored solutions that combine efficiency, technology, and reliability at every stage of the production process, helping our clients operate with maximum safety and competitiveness.

Frequently Asked Questions (FAQ)

A CIP (Cleaning In Place) system automatically cleans process equipment internally, without disassembly, using controlled detergent and rinse cycles.

SIP (Sterilization In Place) uses clean steam at high temperatures to sterilize equipment, eliminating all microbial life before the next batch.

They prevent cross-contamination, ensure product safety, and support compliance with regulatory standards.

Tanks, piping, heat exchangers, sensors, and any product-contact surfaces.

Yes, integration improves efficiency, reduces downtime, and ensures full traceability and validation.