Bioprocessing production equipment

Bioprocessing production equipment with ePROD series

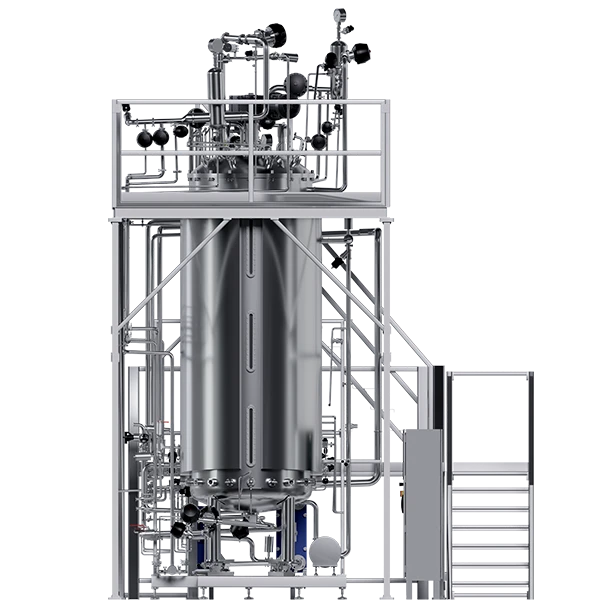

TECNIC introduces the ePROD series, a robust collection of stainless steel bioprocessing production equipment designed to meet the demands of production scale operations. The ePROD Bioreactor stands at the forefront of this series, delivering versatility and high-level efficiency for large-scale production, with capacities reaching up to 2000 liters.

In the single-use domain, the ePROD Bioreactor SU presents a stirred tank reactor solution with volumes up to 1000 liters, engineered to excel in large-scale biomanufacturing and streamline the production process.

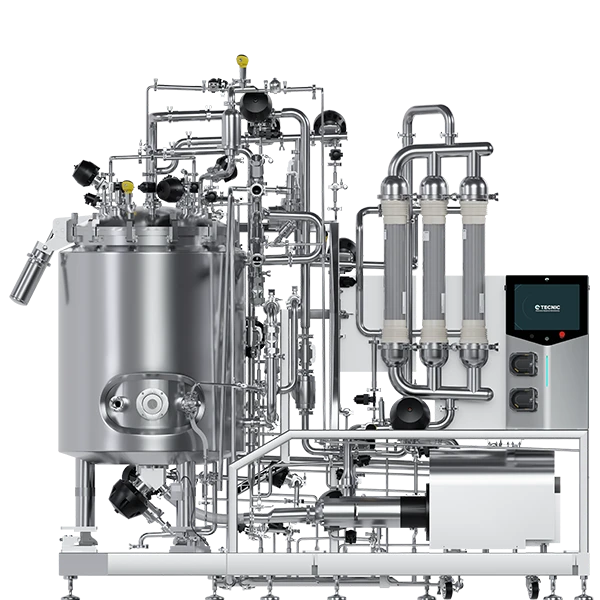

Rounding out the production scale offerings, the ePROD TFF provides an exceptional tangential flow filtration capacity, featuring membrane areas ranging from 7 to 65 m². This equipment is tailored to enhance operational efficiency in industrial-scale bioprocessing.

Together, these systems embody TECNIC’s dedication to advancing production scale biotechnology, offering unparalleled efficiency, scalability, and quality in bioprocessing equipment.